We’re going to put it out there; it’s hardly visionary to expect the manufacturing industry to soon be entirely data-driven. The cutting edge connected technologies that have, or are, emerging present a somewhat obvious premonition into the future whereby the intel garnered throughout the entire supply chain can be shared and used to make operations smoother and the end product more targeted to consumer demand.

These recent technological breakthroughs are destined to have the biggest impact, and will help create the smart factory of the future that in turn drives business growth and improves the sales pipeline.

Internet of Things (IoT)

The IoT is essentially the idea that devices can all be connected to each other via the internet. Machinery, computers and people can be interlinked, creating a spider’s web of information that plays a pivotal part in streamlining your operations and finding weaknesses in your manufacturing process. So for example, once translated,

Yet there’s more potential to go beyond just mass data collection and analysis. The IoT can help manufacturers produce and deliver more quality and robust products that provide a genuine solution to customers. This will not only close the connection gap between manufacturers and end users, but it will help to minimise costs because you’re able to optimise performance from design to finish.

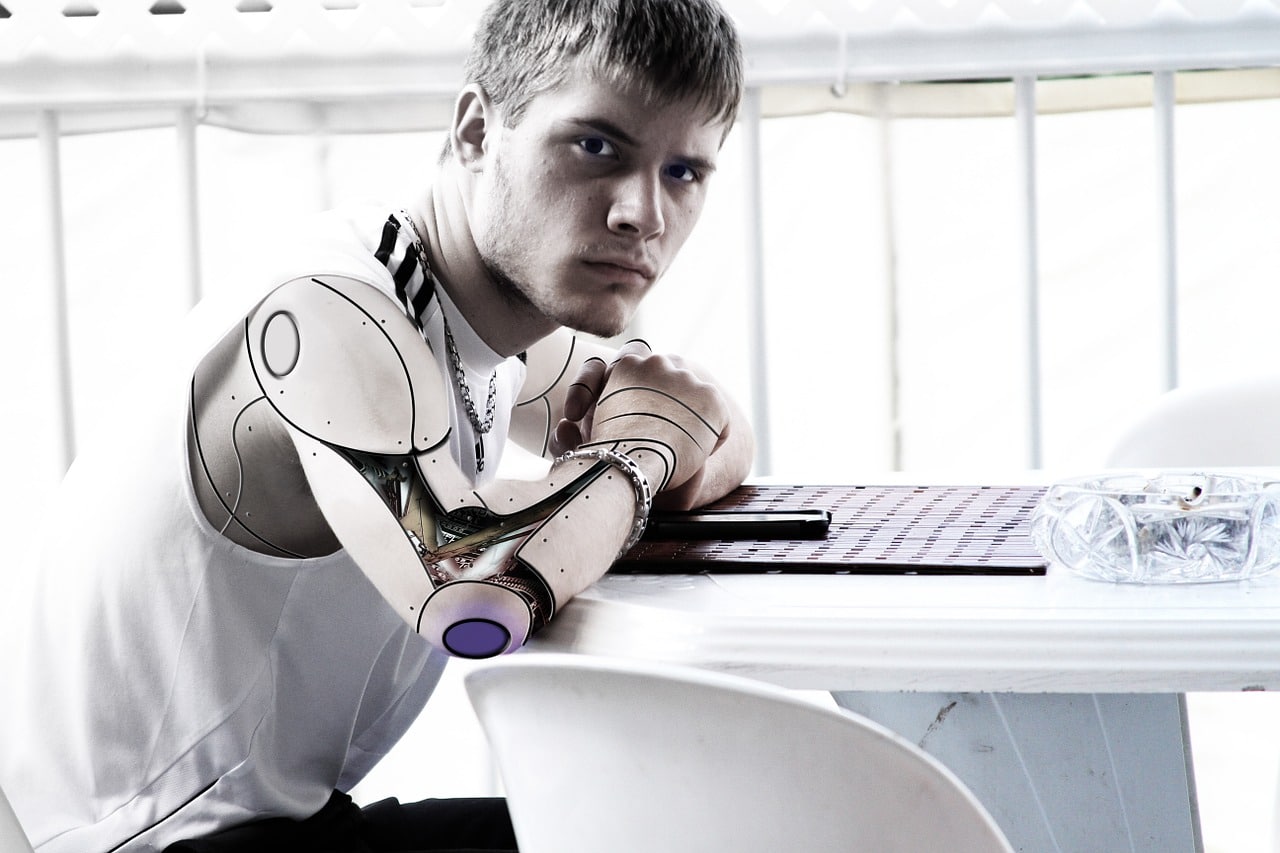

Robotics and Cobotics

Instead of humans attempting challenging manufacturing assembly operations, robots can be used as a safer, easier and faster alternative, minimising error and physical injuries. This human/robotic collaboration is being dubbed ‘cobotics’, and is designed to maintain innovation (human input) whilst improving all the moving parts of the manufacturing process (robot input).

For marketers, robotics presents opportunities for your manufacturing company to spend more time collecting and analysing data, whilst the robotic counterparts can manage the technical procedures, ensuring products are accurately made with a much lower risk of recall.

Augmented reality

You’ve probably heard about Pokemon Go, the crazy popular augmented reality app that literally took over the world. We’re not saying you should create a smartphone app that enables the general public to catch mythical creatures, but we are saying that this is a technology trend that has generated new opportunities for manufacturers to innovate when it comes to product development, helping to refine designs in the early stages.

Augmented reality (AR) allows you to simulate products and how they will be used over time, providing manufacturing marketers with insights into ergonomics, aesthetics and accessibility so you

Big beverage giant Coca Cola used AR to help their prospective retailers decide which display would best fit within their stores from a technical and aesthetic perspective, equipping their sales teams with tablets that virtually positioned the different installments in the individual shops. Providing this instant visibility reduced the amount of sales objections and sped up the purchasing decision cycle.

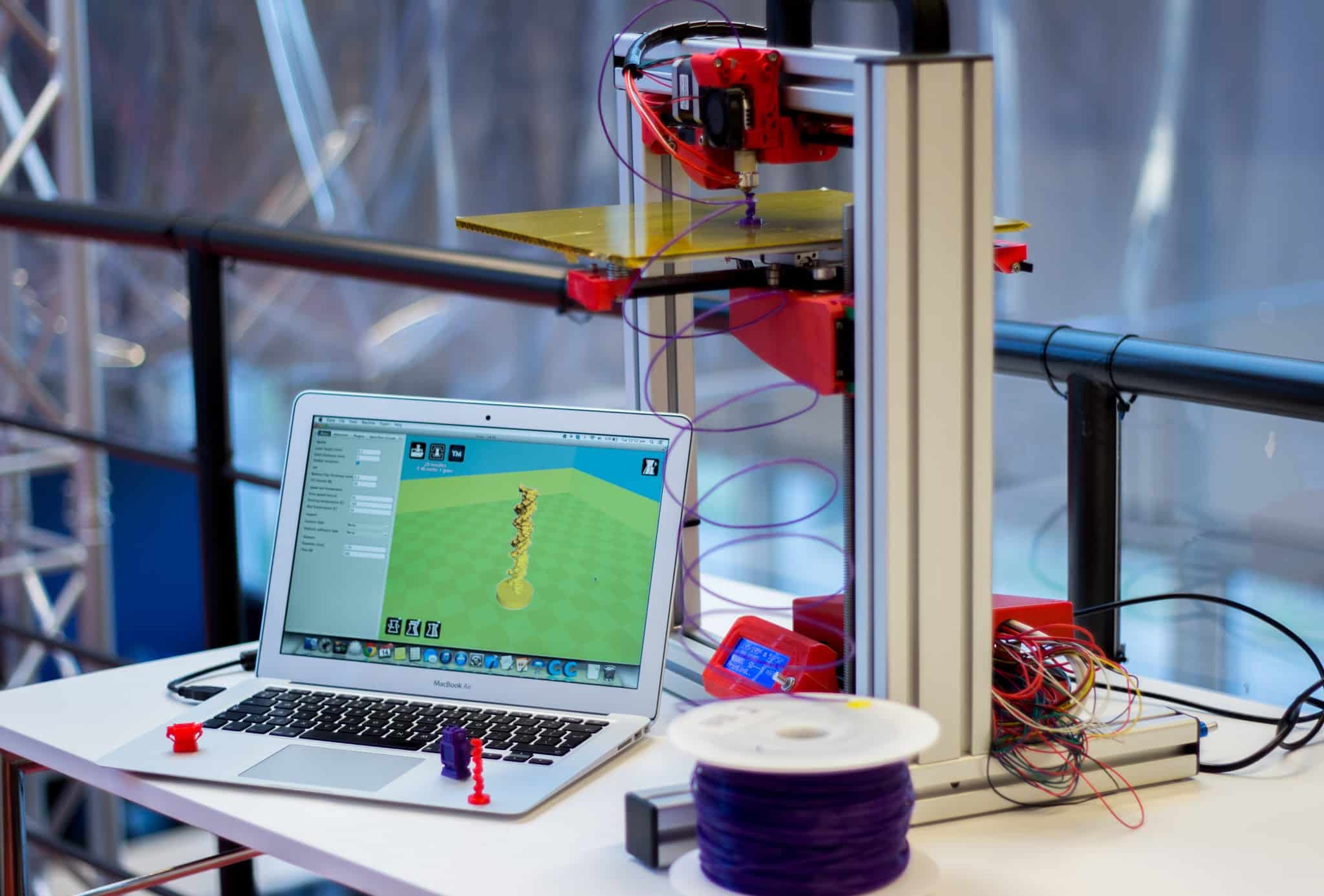

3D Printing

Being prepared is the only way you can get the edge over your competitors, so download The Top UK Manufacturing Challenges of 2016: A Present State and get the honest, in-depth insight you need to move forward and achieve business growth.